CONTROLS FOR DIESEL ENGINE EMISSIONS

The engine’s computer was the main pollution control system in the early years of legally mandated emissions controls made for diesel engines. This meant that starting in the late 1980s, truck engines saw the introduction of full-authority computer-controlled systems far earlier than their automotive equivalents, which tended to rely more heavily on external controls. Catalytic converters, air pump units, exhaust gas recirculation (EGR) systems, and positive crankcase ventilation (PCV) systems were some of the exterior devices utilized on cars starting in the 1970s. That has altered. The modern diesel engine is dependent on a wide variety of external emission control equipment, such as urea injection systems, particle filters, oxidation catalysts, and reduction catalysts. The majority of the emission control modifications for diesel engines must work with the commonly used ultra-low sulfur (ULS) diesel fuel .The operational principles of the devices used on modern diesel engines to restrict pollutants are examined in the next section.

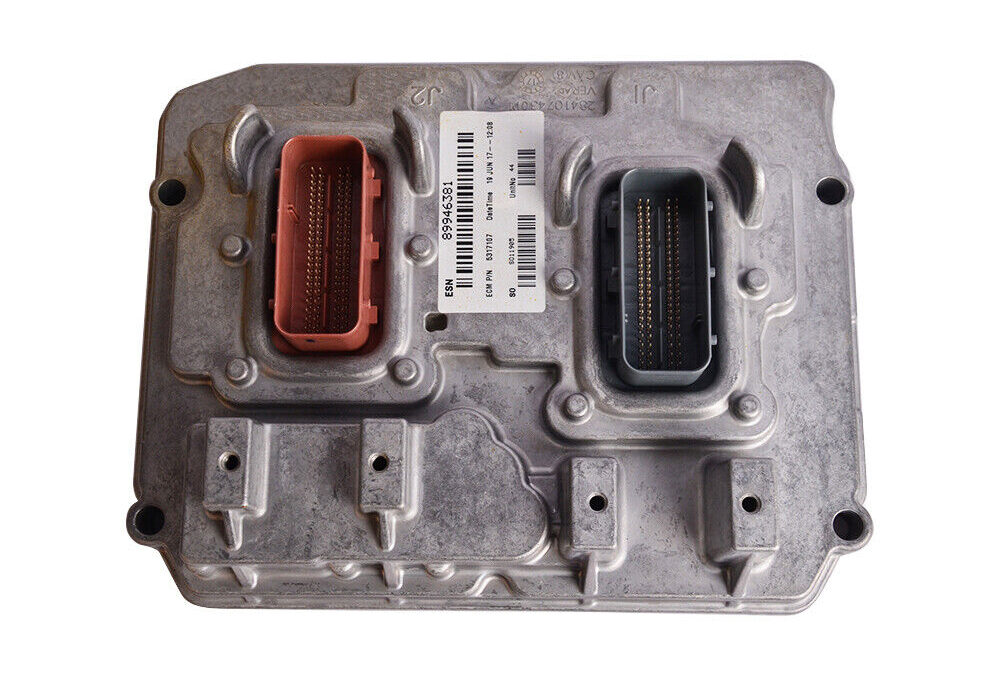

ENGINE CONTROL MODULE

The term closed-loop fuelling will be familiar to those of you who have studied automotive technology. The phrase “closed-loop fuelling” refers to operating a SI gasoline engine while controlling a stoichiometric air-fuel mixture using the signal from the exhaust gas sensor. The low burn technology of the highway diesel engine makes things a bit more complicated since the fuelling algorithm programmed into the electronic/engine control module (ECM) software is never driven by the input of a single sensor. The fuelling algorithm is a collection of ECM-programmed rules and processes that are intended to deliver the engine the desired output and emissions at any given time. It is based on continuously gathered sensor data, operator instructions, and pre-programmed memory instructions. Maps are another name for it. And in modern engines, the fuelling algorithm is necessary to control the engine so that it complies with emissions guidelines during all phases of operation.

Temperature Influences

High-speed processing power is necessary for managing the fuel injection quantity, timing, and features, such as multipulse injection, in diesel engines while adhering to pollution regulations. Most of the time, it is necessary to control combustion temperatures within a small temperature range. When combustion temperatures are in the lower range and the air-fuel ratio (AFR) is richer, HC emissions typically rise. On the other hand, when AFR leans out and the combustion temperatures are in the upper range, NOx emissions often rise.

Timing variables

It’s also critical to remember that noxious emission characteristics are influenced by the time of injection or, more particularly, ignition. While overly retarded timing can significantly increase HC emission, retarded timing tends to lower NOx emission. Timing errors of as small as 1 degree crank angle might result in a 10% increase in NOx or HC percentage in the exhaust gas. Because of this time sensitivity, computer control of CI engines has become crucial when trying to comply with pollution regulations.

Generally speaking, advancing the timing of the engine will raise engine temperatures, which tend to increase NOx emissions, while retarding the timing might result in incomplete fuel combustion, which can increase HC emissions. The basic fuel maps established by the OEM must typically be defeated in order to alter injection time; this technique is prohibited and is more frequently used on low duty diesel engines than heavy duty ones. The multipulse injection capability employed in all modern diesel engines, which maximizes emissions, power, and fuel efficiency, has substantially improved injection timing precision for those who do not cheat.

CONTROLS FOR EXTERNAL EMISSIONS

You would have trouble telling which engine family they belong to if you looked at any truck diesel engine series produced in 2001 and compared it to its series counterpart now. Modern diesel engines employ a wide range of external pollution control equipment. We examine a few of these gadgets in further detail in this section.