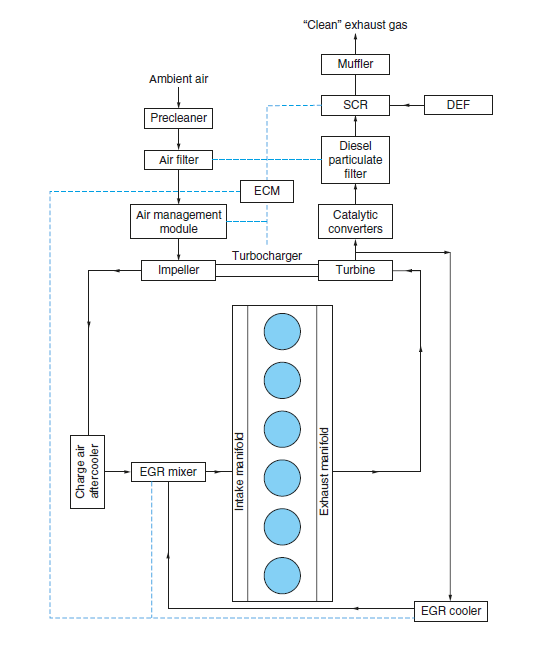

LAYOUT OF THE EMISSIONS CIRCUIT

The complex pollution control circuit that clutters the outside of a diesel engine built after 2010 makes it highway-compliant. On today’s highway diesels, DPF and SCR are virtually always utilized. Without SCR, one must rely significantly on high % EGR cuts, which might contaminate internal engine parts.

ACCESSORY DEVICES

The diesel engine has evolved over time in an effort to comply with ever stricter pollution regulations. Here are a few of the recent adjustments and how they have contributed to emissions reduction. The majority of them are still in operation or have a modern diesel engine equivalent.

Injectors for VCO

valve closes orifice (VCO) injectors were first discussed. In hydraulic injection injectors, reducing or eliminating the nozzle sac capacity lessens the cylinder boil/dribble of sac fuel after injection. All modern injectors employ this nozzle design idea.

Air Charge Cooling

Effective intake air cooling reduces combustion temperatures, which reduces the likelihood that the nitrogen in the air mixture will be oxidized and produce NOx. Charge air coolers that are air-to-air cool air more efficiently than ones that use engine coolant. The ability of the charge air cooler to cool will be compromised by anything, and this will cause increased NOx emissions. For this reason, when charge air heat exchangers clog, codes are recorded.

turbochargers with variable geometry

Particularly when ECM driven, variable geometry turbochargers (VGTs) have the ability to modulate boost based on the fuelling and emissions algorithms, which may significantly reduce both HC and NOx emissions. VGTs operate efficiently across a considerably larger load and rpm range. Most diesel engines that comply with highway regulations employ VGTs rather than constant geometry turbos. A constant geometry turbocharger is often one of two turbochargers utilized in series turbocharged engines nowadays.

Pistons from Low Headland

The top compression ring is raised by low headland volume pistons such that it is almost at the piston crown’s leading edge. The headland gas volume is kept to a minimal as a result. The amount of headland gas can enhance HC emissions and has a tendency to be unreactive. Within a short period of time, the design of diesel engine pistons underwent some significant alterations as a consequence of the engine designers’ desire for reduced headland volume pistons. Nowadays, the majority of diesel engine manufacturers choose trunk-type steel pistons with reduced headland volumes, such the Mahle MonothermTM.

Aneroids

Despite the fact that the majority of manifold boost measurement devices have already been discussed in other chapters of this book, a few of the more popular techniques for reducing smoke on older hydromechanical engines are briefly addressed here for convenience. Aneroids are by definition instruments for monitoring low pressure. In essence, they gauge manifold boost and postpone engine feeding until the cylinder has enough air to burn the fuel meter by the injector. Although aneroid functioning varies by OEM, aneroid technology is still relevant today since the SAE J1667 test fields were created using an understanding of how aneroid technology operates. To put it another way, J1667 opacity (smoke emission) standards compliance is based on a field test that is 30 years old.