Different DPFs

Our main goal in this part is to concentrate on the post-2007 DPFs that are required. The type of DPF employed on a certain diesel engine is mostly dependent on the typical exhaust temperature. Three different forms of DPF are often in use:

A catalyst. Integrated within a canister together with multistage catalytic converters and what was formerly the muffler is this more popular version of DPF. The most accurate description of it is probably “complete aftertreatment device.” The majority of highway vehicles use catalyzed DPFs, which may undergo both passive and active regeneration cycles. They are appropriate for situations where the typical exhaust temperature is higher than 225 °C (437 °F).

Not catalyzed In diesel-powered, work-related cars that operate at low engine load for extended periods of time, this sort of DPF is necessary. Cement trucks, fire vehicles, and garbage packers are examples of common uses. Noncatalyzed DPFs can only perform active regeneration cycles, and they are controlled by a separate control module from the engine ECM. The J1939 data backbone assigns the noncatalyzed DPF control module an address, and it uses the data bus to interact with the engine ECM. On engines manufactured after 2010, the aftertreatment module may also control the SCR system.

- Filter for low temperatures (LTF). The LTF is made to take out entrapped diesel particulate pollutants from low-load applications. They employ catalysts for oxidation. The frequency of cleaning cycles is often higher, and accumulated ash must also be frequently removed. LTFs are intended for use in situations where the average exhaust temperature is greater than 200°C (392°F) but less than 225°C (437°F).

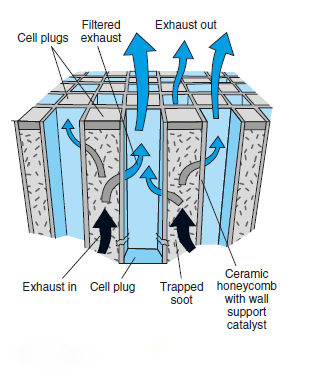

Operating Principles for DPF

The concept behind a DPF is that engine exhaust soot initially gathers on the container’s walls. DPFs are generally intended to operate in self-regeneration mode by engine makers. This indicates that soot gets burnt off in a process known as a regeneration cycle after it reaches a certain degree of accumulation. Most of the time, during normal operation, the regeneration cycle will start when exhaust temperatures are high enough. Self-regeneration is the term used when this regeneration occurs without the aid of additional fuel or air injection into the exhaust stream. Passive regeneration is another name for self-regeneration: By engine OEM, nomenclature varies.

Most of these devices include heat shielding since the operating temperatures of the combined oxidation converter and DPF can approach 600°C (1,112°F). Both single and twin canister variants are utilized, depending on the engine and its power rating. Typically, single and multiple canisters are described as follows according to their horsepower rating:

- One canister: 600 BHP maximum (447 kW)

- Dual canister: at least 600 BHP (447 kW)

In cases when the operating conditions do not favor a self-regeneration cycle, regeneration can also be aided by the injection of some fuel (diesel), occasionally with the help of spark ignition. Active regeneration is the term for this type of regeneration. Typically, fuel for an active regeneration cycle is given at the required charging pressure from the fuel subsystem. For instance, this would be 250 psi (17 bar) provided via an electromechanical injector on a Caterpillar ACERT C15.

Similar DPF devices are used by the majority of diesel engine OEMs, although they are handled differently. The main distinction between OEMs utilizing catalyzed DPFs is whether an active regeneration cycle needs a spark plug’s aid.